Dagoberto Maradiaga has been making boots and footwear for over 30 years. He started in his fathers shop in Honduras before he was even in his teens. Apprenticing under a master, Dagoberto was instilled a passion for the craft, learning skills and techniques of a lifetime in only years.

After deciding to dedicate his skills to a truly American art form, the cowboy boot, he immigrated to the United States and went into custom boot making. Upon arriving to California, Dago began working with the legendary Nudie Cohn at Nudies of Hollywood in North Hollywood. While there he worked alongside other talented craftsmen and met the elite of the entertainment industry. He later worked with famous taylor to the stars Manuel, where he further mastered his craft as head boot maker.

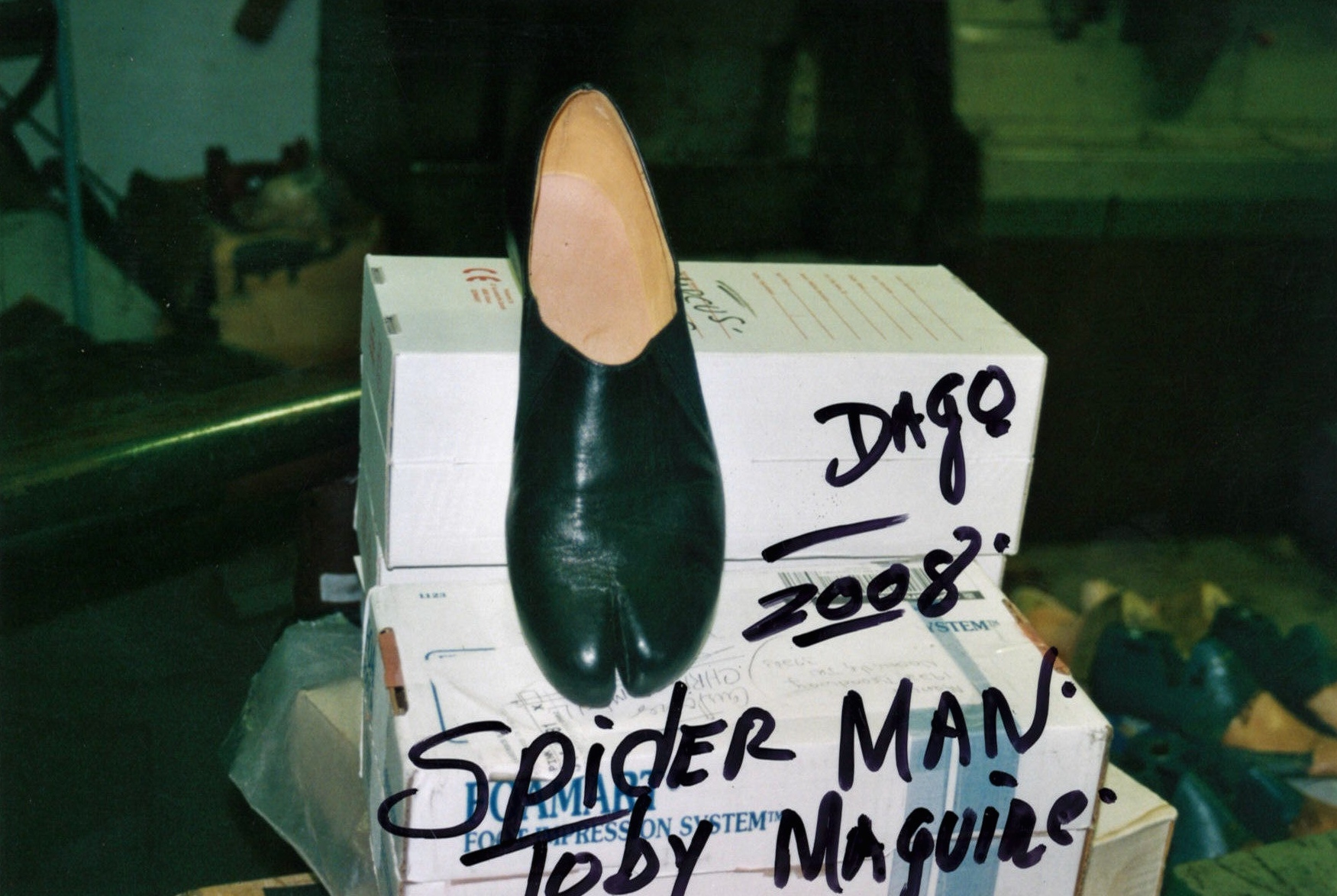

Dago opened his North Hollywood shop “Dagos Boots” in 1984 where he continued working with a variety of celebrities as well as Hollywood studios where he soon became recognized for his talent and inimitable style. Dago’s work can be seen in many blockbuster films such as Wild Wild West, The Patriot, Night at the Museum and the Spiderman trilogy, to name a few. His prolific work spans decades.

The Art of Custom Boot Making

Here is a simplified step by step breakdown of our creative process:

1. SIZING - Drawings and precise measurements are taken to ensure an exact fit and maximum comfort.

2. LAST SELECTION - A custom last (mold) is made based on the measurements and the design of the template for the boots desired.

3. LEATHER SELECTION - The leather used for the boot is selected by the client based on color, texture, quality, brand and material desired.

4. UPPER - The upper part of the boot is assembled based on the desired template by sewing machine and adhesion to custom specifications approved by the client.

5. LASTING - This is an integral part of the process which begins to transform the leather into a form that more closely resembles a boot. The upper is mounted onto the last and a channel is then carved around the perimeter of the boot in order to be welted with goodyear style construction.

6. THE SOLE - A steel shank is placed on the leather sole of each boot before attaching the heel to reinforce its structure and ensure durability. A smooth rubber sole and a heel are then attached to the bottom for a stylish and modern look and feel.

7. FINISHING - Each boot is then painted, polished and finished to the clients’ taste and our standards of quality and perfection.

Through years of practice, Dagoberto Maradiaga has refined his techniques in the various stages of developing one single pair of shoes. Unlike mass production where machinery replaces the labor, there are various steps involved from molding to finishing an item. Based on the desired style, the process will vary. Uniqueness is the key element in custom boot making and it is our wish to share with our clients the detail and intricacy put into each piece.

Clients and Credits:

Ben Harper

Amy Adams (Night at the Museum, 2009)

Joan Sebastian

Cher

Batman, 1999

David Arquete, 2004

The Green Mile (Warner Bros, 1999)

Burt Reynolds, 2001

Robert Di Niro

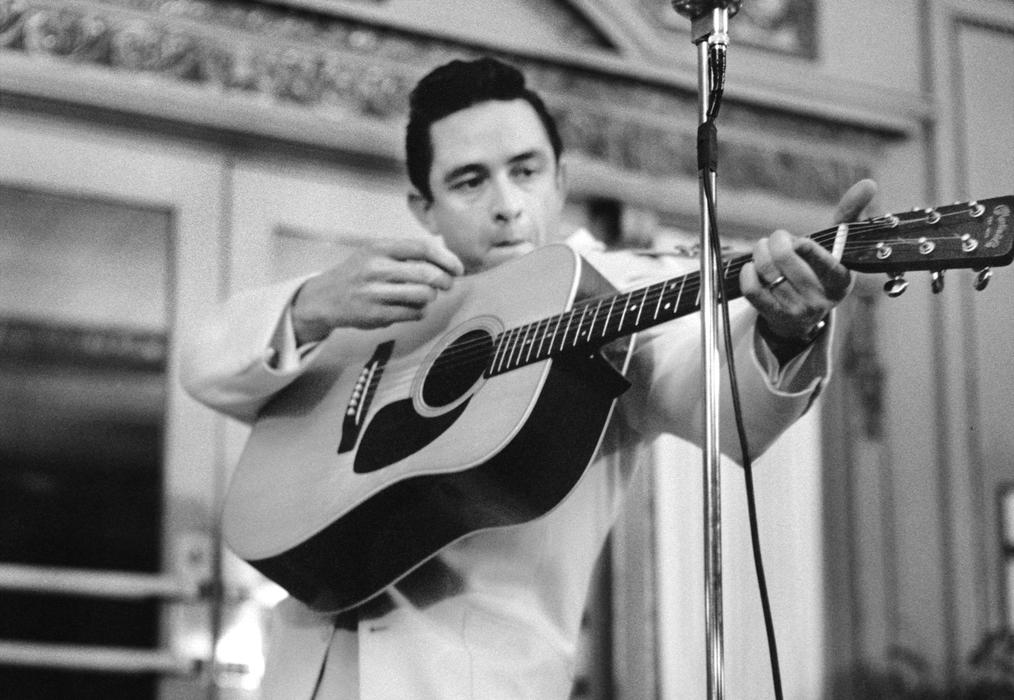

Custom Lasts belonging to Johnny Cash, Sylvester Stallone, Hank Williams Jr and Glen Campbell

Spider Man (Sony Pictures, 2002)

Spider Man - Toby Maguire - (Sony Pictures, 2007)

Joan Sebastian

Jennifer Nicholson

Los Tigres Del Norte

Riders In The Sky, 1995

David Arquete, 2000

Johnny Cash

Dwight Yokam

Hank Williams Jr.